Quality Control Computer Vision AI System

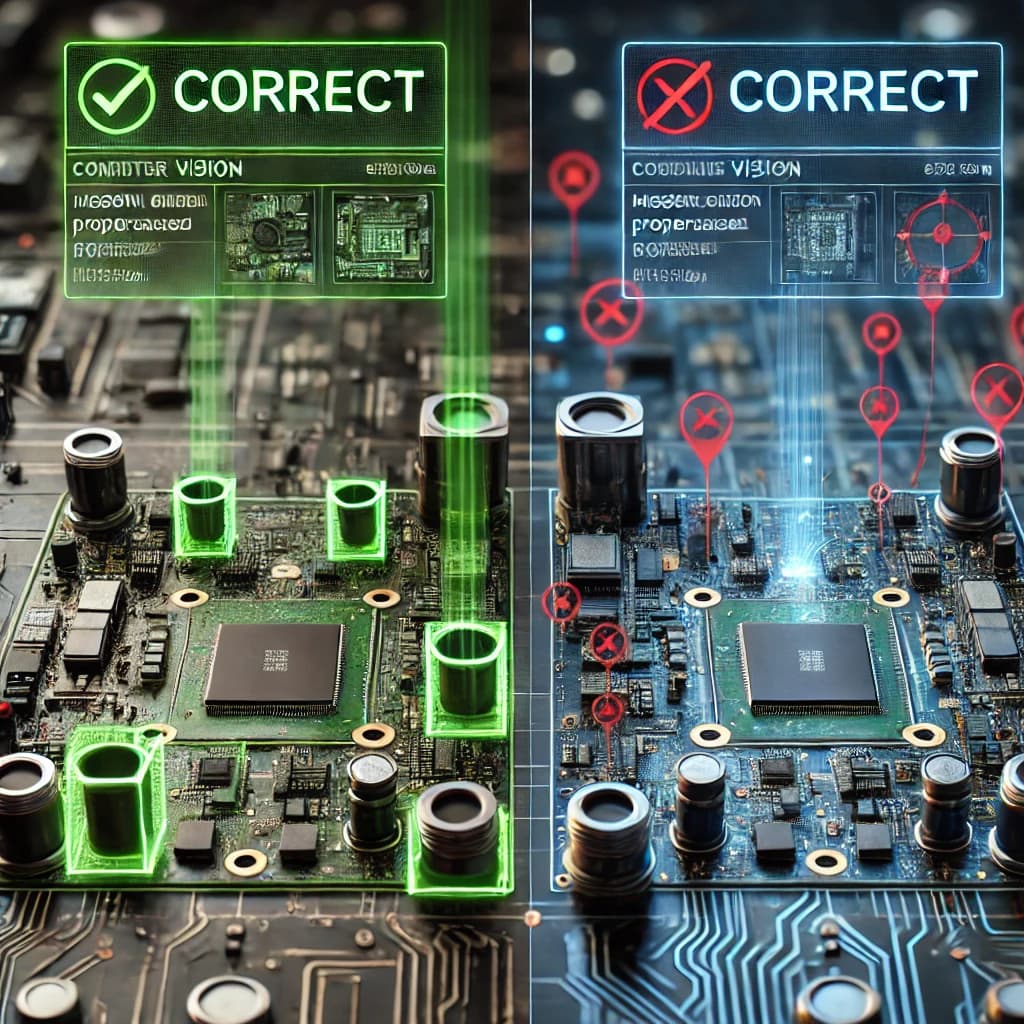

A computer vision system trained on manufacturing data to identify production faults and quality defects, ensuring high standards in manufacturing processes.

Wed Jan 15 2025

AI

Computer Vision

Quality Control

Manufacturing

Automation

This project leverages computer vision and AI to enhance quality control processes in manufacturing. The system is trained on datasets of high-quality products and common fault scenarios, such as misaligned components or surface defects. By analyzing high-quality images during production, it detects and flags potential quality faults, reducing waste and improving efficiency in manufacturing.

Features

- Fault Detection: Identifies quality faults such as misaligned components, surface defects, and structural issues.

- High Accuracy: Trained on diverse datasets, ensuring reliable identification of both common and rare defects.

- Real-Time Inspection: Processes high-quality images in real-time to integrate seamlessly into production lines.

- Defect Categorization: Classifies faults to prioritize critical issues for immediate attention.

- Efficiency Improvement: Minimizes manual inspection time and reduces production delays caused by undetected faults.

How It Works

- Dataset Preparation: Collect images of high-quality products and faulty examples, including scenarios such as misaligned components and surface defects.

- Model Training: Train AI models using computer vision techniques to differentiate between acceptable and faulty products.

- Integration: Install high-resolution cameras on manufacturing lines to capture product images.

- Analysis: AI models analyze captured images in real-time to identify faults.

- Feedback: Detected faults are flagged, and data is relayed to operators for immediate corrective action.

Challenges Faced

- Creating a diverse and representative dataset for training AI models.

- Ensuring accurate fault detection under varying lighting and environmental conditions.

- Integrating real-time processing into high-speed manufacturing lines.

Future Enhancements

- Expanding detection capabilities to include more complex fault types and variations.

- Incorporating predictive maintenance features to anticipate potential manufacturing issues.

- Developing a feedback loop for continuous improvement of AI model accuracy.

- Integrating with cloud-based systems for centralized fault tracking and analytics.

- Enabling compatibility with various manufacturing setups and product designs.